Online Catalogue

- Home

- Online Catalogue

- Grain Storage Silos

- Flat Bottom Grain Storage Silos

- Hopper Bottom Grain Storage Silos

- Grain Handling Equipments

- Belt Conveyors

- Vibro Grain Seperator

- Distributors

- Inclined Chain Conveyors

- Elevator Towers and Support Towers

- Enclosed Belt Conveyors

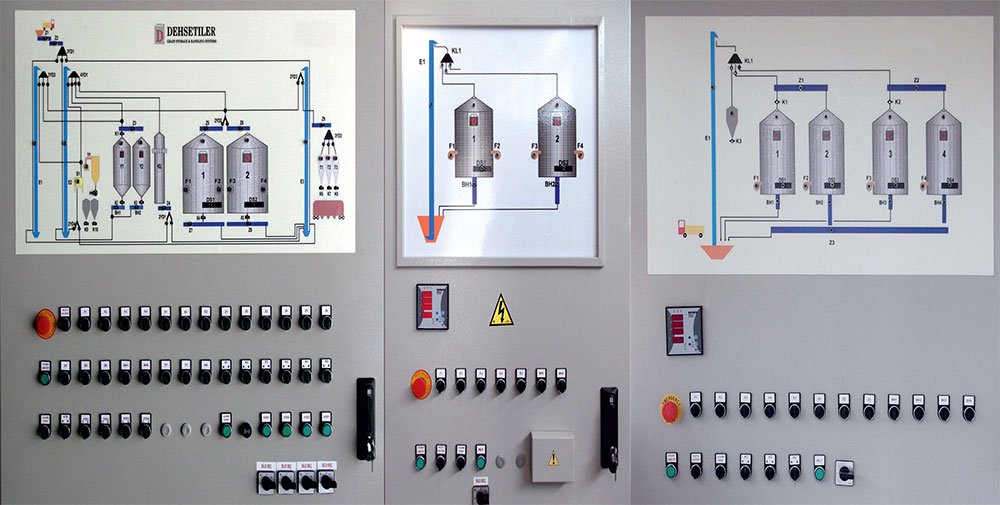

- Control Pannel

- Bucket Elevators

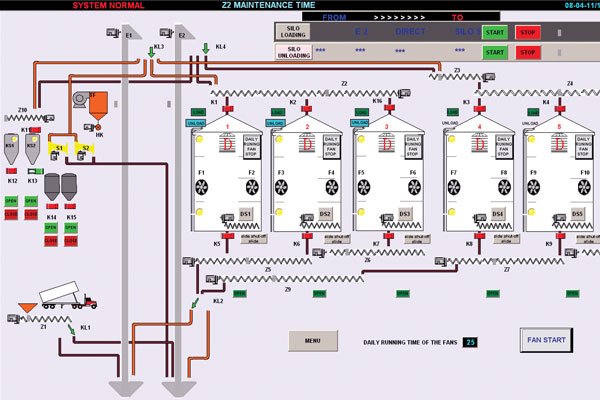

- Automation Systems

- Drum Type Grain Seperators

- Catwalks

- Chain Conveyors

- Compact Feed Mills

- Hangars

- Grain Drying Systems

All Dassilos® silos are designed according to the specifications and standards given below; – Dynamic analysis of the silo structural system is done according to the seismic and soil conditions of the area which the silos will be installed. – Snow load is calculated according to conditions of the area which the silos will be installed. – Wind load is calculated according to the height of the silo especially for the empty case of silo. – Static and dynamical analysis of the silo is done for the case of 25oC temperature change. – Static and dynamical analysis of the silo is done according to the vertical and horizontal load of grain. – After the designing with CAD-CAM programs, the silos are manufactured with CNC controlled machines, quality control is done by the quality control department. Silos with all accessories are manufactured from 600 gr/m2(G210) hot dip galvanized, high tensile strength steel sheets. The strength of the steel is 450 Mpa. The steel used for silo manufacturing is in S390GD+Z600 standards and have the analysis certificates.Theside wall sheets are chromate coated besides the galvanize coating. This chromate coating protects the galvanize coating from the harmful effects of the handling, carrying and storage. By customer satisfaction, Dassilos becomes well known grain silo manufacturer.

Flat Bottom Grain Storage Silos

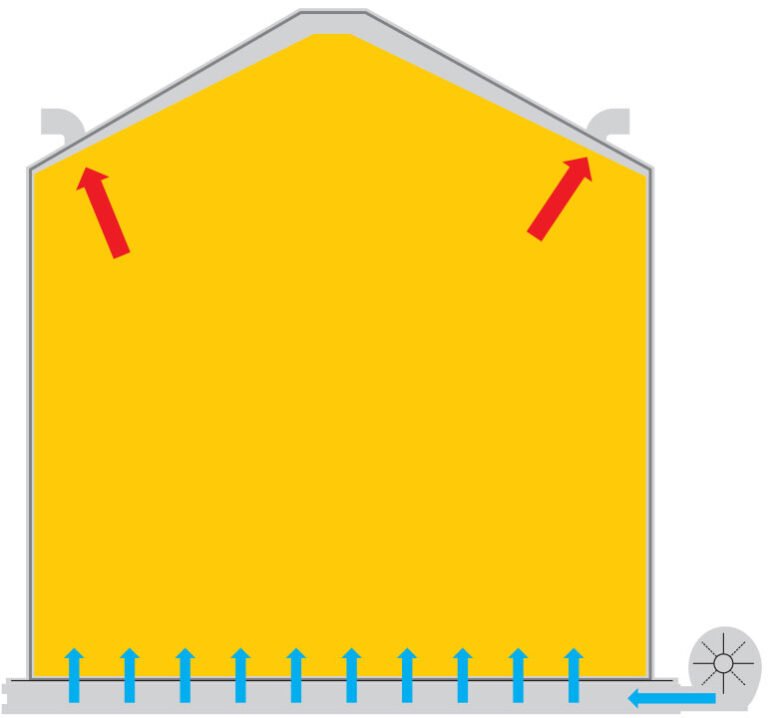

The roof of the silos have a 30 degrees slope angle. This angle is nearly 2 degrees less than the filling angle of the grain. By this difference, there would be no grain load at the roof either the silo is full to its top. And a space occur between the grain layer and the inner part of the silo roof. By this space, the grain and steel sheet do not touch each other and no condensation occurs because of the difference between inner and outer temperature of the silo. And, by the ventilation outlet at the roof, natural air circulation exists. This natural air circulation is supported by aeration fans and the grain is stored for a while.

Dassilos® manufactures silos using 100 mm corrugated sheet. This corrugation is 12% stronger than conventional 76 mm. corrugated sheets. The corrugated sheets have 110 cm. height results 30% fewer seams between sheets for faster erection and beter weather protection. The sidewall sheets are supported by the heavy duty stiffeners to carry extra load.These stiffeners transfer the drawdown loads to foundation. In the case of earthquake,these stiffeners carry the seismic loads.For this reason,the stiffeners on Dassilos® silos are thicker and manufactured from more tensile strength steel. The stiffeners are added each other by a plate at their forehead. The roof panels are triangle in shape and two sides of the panels are roll formed as a 90 mm. deep trapeze. Roof panels have 7,5 degree with every 5 cm. on them to increase its strength 67%.

Ladders, Entrance – Inspection Doors

Inner,outer ladders and safety cage for outer ladder, roof ladders are manufactured complying with the latest safety standards by Dassilos®. Entrance and inpection doors are used for entering silo and inspecting the grain inside silo.

Silo Foundations

All silos either flat bottom or hopper bottom are placed on foundations which transfer the loads of the silo, grain, equipments,etc. to the soil. Silo foundations are designed in 2 types according to tunnel unloading or side unloading . Aeration channels, unloading screw auger channels, unloading gate places are built while foundation construction.

Aeration Fans and Aeration Outlets

Aeration system of the silo is very important for long term storage of the grain in silo. Aearation fan capacity is designed according to the silo capacity, grain type inside silo, silo height. Ventilation outlets on the roof helps the natural aeration at roof part preventing condensation in the roof part which is occurred by temperature difference between inside and outside the silo roof panel. According to the weather conditions of the place where silos are built, exhaust fans on the roof would be necessary to enchance the aeration capacity for roof aeration.

Temperature and Level Monitoring Systems

Grain inside silo have to be controlled well to prevent spoiling. Our silos are equipped with temperature monitoring systems to monitor grain temperature inside silo. If the grain inside the silo gets warm because of its moisture this can be monitored by temperature monitoring system. Number of cables and sensors are selected according to the dimensions of silos and the grain type to be stored. Monitoring is done by mobile monitoring unit. Also automatic monitoring and reporting equipments are available as option.

Sweep Augers

Sweep augers are used to handle the grain to the center of silo. They are used when the grain flow at the center is over. Because of the friction of grain, the grain remains inclined. Thus it have to be handled to the center by sweep auger. Dassilos® are designed for easy use, without failure. They are equipped with brush electric transferring system which prevents entering silo for electric connection. Well designed sweep augers are in 2 types as Normal duty and heavy duty.

Unloading Augers

Unloading augers are used to unload grain inside the silo. They are designed to help repair and maintenance work while silo is full. They are equipped with 1 center and 2 intermediate wells to help easy unloading. Until the grain flow from the center of silos, intermediate wells have to be closed.

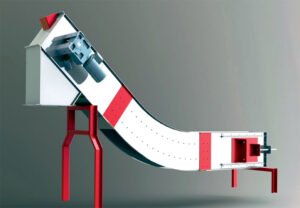

Belt Conveyors

Belt conveyors are used at pulse, seed, rice industry to prevent grain damage. As the grain moves only on the belt, it is easy handle different type of grains without any mixing. When compared with chain conveyors, handling to longer distances with higher capacities is possible with belt conveyors. There are 2 types of belt conveyors: Open Type and Enclosed Belt Conveyors.

Technical Specifications

| Model | Capacity (ton/h) | Belt Speet (m/sec) | Belt Width (mm) |

|---|---|---|---|

| DMI 0BC 400 | 50 | 1,5 | 400 |

| DMI OBC 500 | 100 | 1,5 | 500 |

| DMI OBC 600 | 200 | 1,5 | 600 |

| DMI OBC 800 | 300 | 1,5 | 800 |

| DMI OBC 1000 | 400 | 1,5 | 1000 |

| DMI OBC 1200 | 500 | 1,5 | 1200 |

Product Images

Vibro Grain Seperator

Vibor seperators are used to remove the impurities from the grain by vibrating sieves. According to the kind of grain, they are equipped with air channel or tarar to remove dust from the grain.

Technical Specifications

| Model | Dimensions (mm) | Capacity(t/h) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | PRE CLEANING | PRECISION CLEANING | ||

| DCS 80×160 | 1320 | 2280 | 1450 | 1400 | 700 | 150 | 20 | 8 | 500 |

| DCS 100×150 | 1620 | 2280 | 1500 | 1400 | 900 | 150 | 25 | 10 | 700 |

| DCS 100×200 | 1620 | 2650 | 1800 | 1600 | 900 | 150 | 30 | 14 | 900 |

| DCS 150×240 | 2300 | 3050 | 2300 | 1700 | 1400 | 150 | 50 | 18 | 1100 |

Product Images

Distributors

Distributors are used to channel grain to different points.They are 2 types, single inlet and multi inlet. They are controlled by magnetic sensors.

Inclined Chain Conveyors

Inclined chain conveyors are used to handle the grain to high level point by inclination of chain conveyor. Thanks to its horizontal – vertical combination design, it reduces the handling equipment cost.by using this type of conveyor, you may place bucket elevators without manhole, reduce the height of bucket elevator. You may transfer grain vertically by this type of conveyor without bucket elevator.

Technical Specifications

| Capacity (tons/hour) | 30 | 60 | 60 | 100 | 100 | 150 | 150 | 200 | 200 | 250 | 250 | 350 | 350 | 500 | 500 | 600 |

Product Images

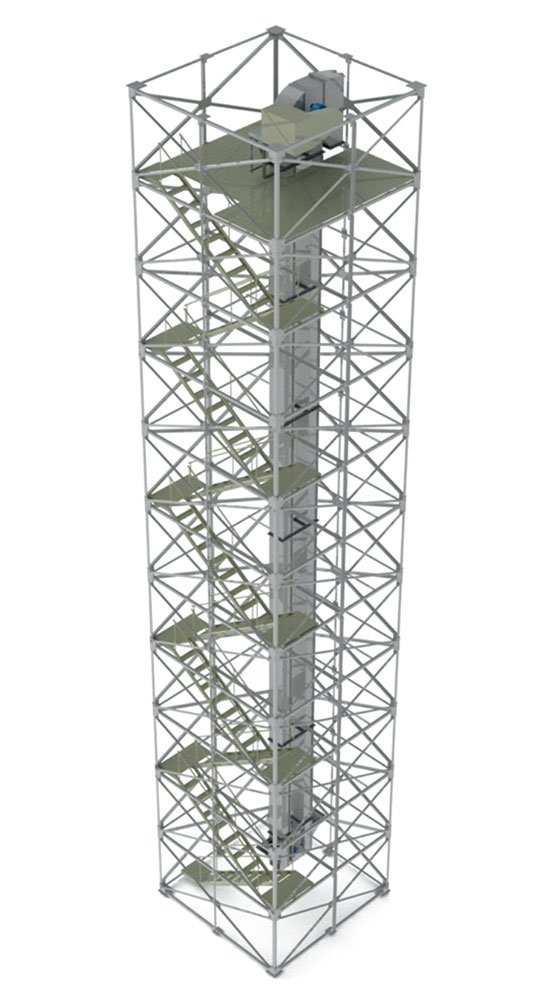

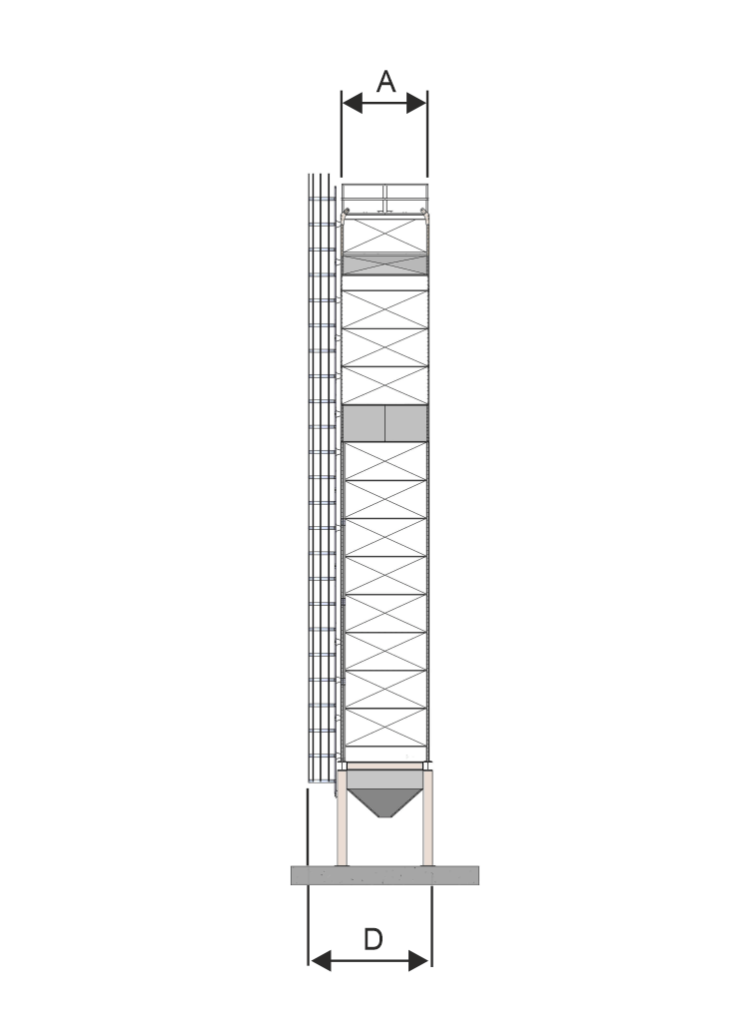

Elevator Towers and Support Towers

Elevator towers are used to support bucket elevators. There might be ladder with 2 side banisters inside the tower with resting platform optionally. There are also platforms at the distributor and elevator head level. You may transfer grain vertically by this type of conveyor without bucket elevator.

Product Images

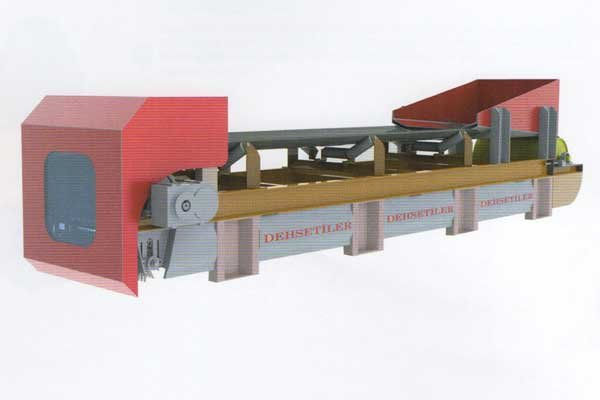

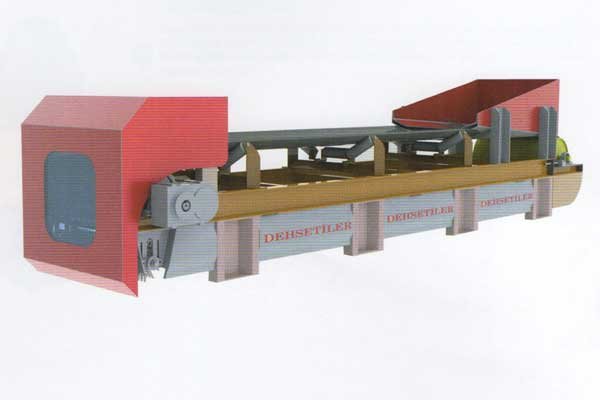

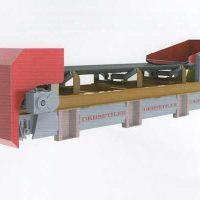

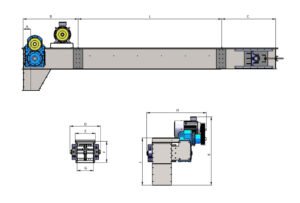

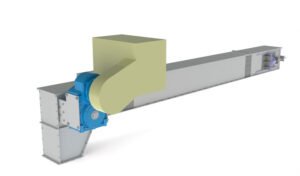

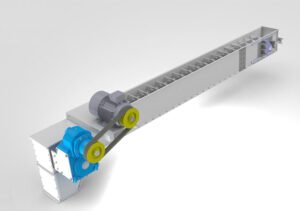

Enclosed Belt Conveyors

Kapalı tip bant konveyörler; toz ve granül ürünlerin hassas olarak yüksek kapasitede ve uzak noktalara iletimini sağlarlar. Tabanda aşınmayan dayanıklı polietilen levha kullanılarak bant sürtünmesi engellenir. Üst kapaklar kolay açılır ve ürünü dış etkenlerden korur. Tahrik tamburu kauçuk kaplanarak patinaj engellenmiştir. Dassilos® kapalı tip bant konveyörlerinde ürünler birbirine karışmadan taşınırlar.

Technical Specifications

| Model | Capacity (ton/h) | Belt Speed (m/sec) | Belt Width (mm) |

|---|---|---|---|

| DMI CBC 400 | 50 – 100 | 1,2 – 3 | 400 |

| DMI CBC 500 | 100 – 200 | 1,2 – 3 | 500 |

| DMI CBC 600 | 150 – 200 | 1,2 – 3 | 600 |

| DMI CBC 700 | 200 – 400 | 1,2 – 3 | 700 |

| DMI CBC 800 | 250 – 500 | 1,2 – 3 | 800 |

| DMI CBC 1000 | 350 – 700 | 1,2 – 3 | 1000 |

| DMI CBC 1200 | 450 – 900 | 1,2 – 3 | 1200 |

| DMI CBC 1300 | 500 – 1000 | 1,2 – 3 | 1300 |

Product Images

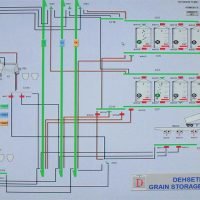

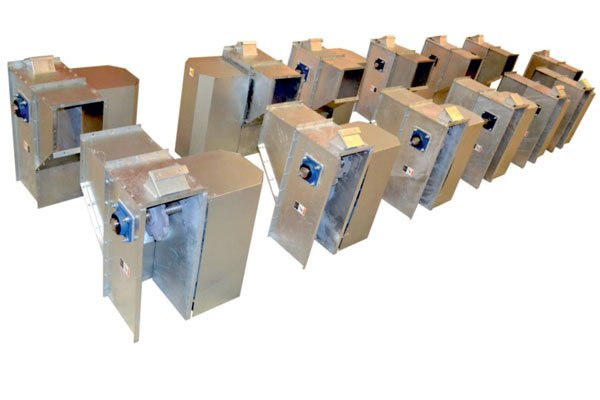

Control Pannel

Electrical panels that control all equipment used in the grain storage system are designed in various types, manual and automatic. In the manual control system, equipment is electrically connected to each other and is made to work and stop in a certain order. In this way, the continuity of grain flow between the equipment is ensured.

Product Images

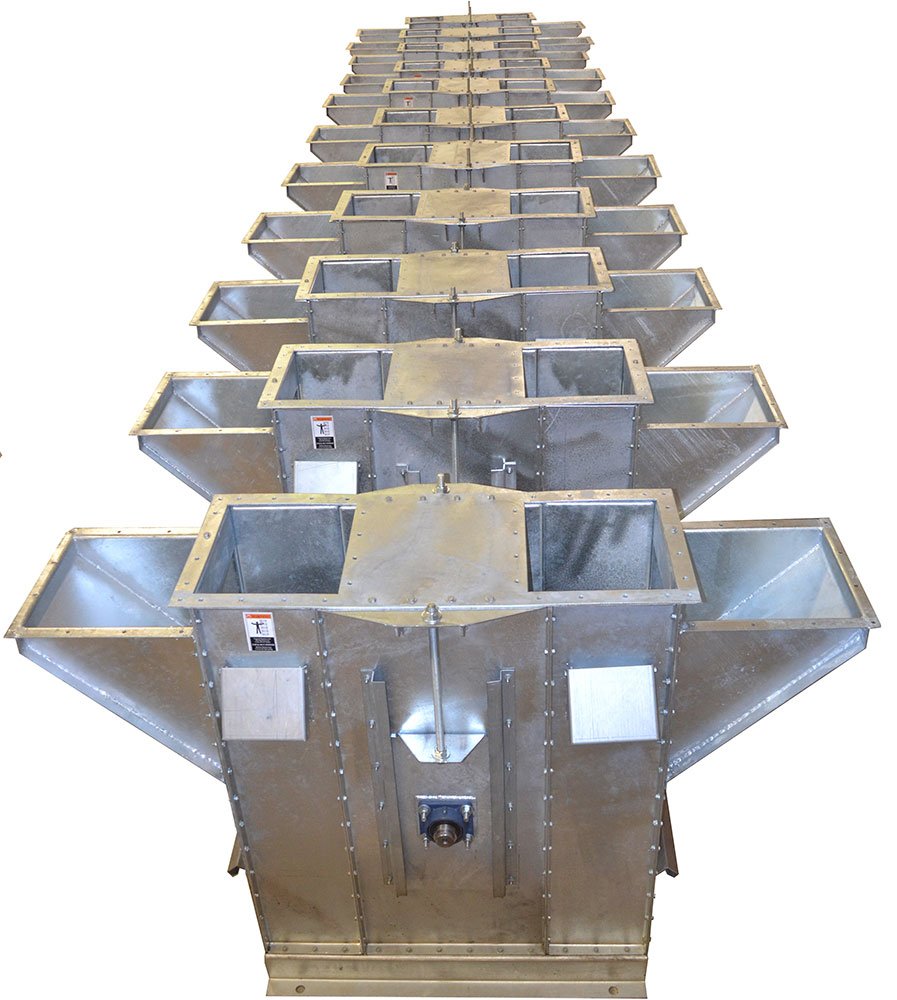

Bucket Elevators

Bucket elevators are used for vertical handling of grain. They are manufactured in various capacities and heights. Dassilos® use high strength plastic buckets on the elevator manufacturing. The rubber belt have high carrying capacity. Bucket elevators are manufactured from hot dip galvanized steel sheets. Thanks to completely bolt-nut assembly bucket elevator mounting is so easy. Bucket elevator’s boot and head section are manufactured for heavy duty, with hinged legging inspection doors for easy inspection and maintenance. Trunks has very good isolation against weather conditions and dust. Bucket elevators are equipped with ladders, platforms, support ropes which are optional.

Technical Specifications

| Capacity (tons/hour) | 30 | 60 | 60 | 100 | 100 | 150 | 150 | 200 | 200 | 250 | 250 | 350 | 350 | 500 | 500 | 600 |

Product Images

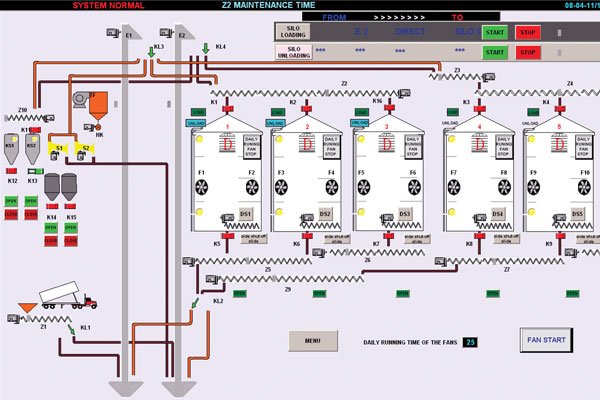

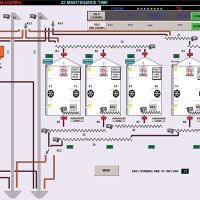

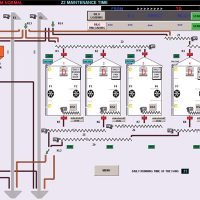

Automation Systems

In automatic control, the handling equipments are operated in an order by the help of PLC to prevent overload. Semi automation system only controls the operation of handling equipments. Full automation system controls the grain level in silos continuously, it operates the aeration system is there is failure in the full part of silo. It detects grain temperature, grain level, system failure, maintenance times full time, save reports, warns the operator by full automation using SCADA. Bucket elevator’s boot and head section are manufactured for heavy duty, with hinged legging inspection doors for easy inspection and maintenance. Trunks has very good isolation against weather conditions and dust. Bucket elevators are equipped with ladders, platforms, support ropes which are optional.

Product Images

Drum Type Grain Seperators

Drum type grain separators are used for pre-cleaning of grain. The Grain is separated by the help of perforated drum with different diameter holes. This drum has self cleaning brush. The capacity can be adjusted by the inclination of drum for different kind of grains. With its dust collection unit, dust in the grain can be removed.

Technical Specifications

| Model | Diameter of dream (mm) | Quantity Of Screens (unit) | Capacity (t/h) |

|---|---|---|---|

| DMI DC 50 | Φ 50 | 2 | 50 |

| DMI DC 80 | Φ 750 | 2 | 80 |

| DMI DC 100 | Φ 900 | 2 | 100 |

| DMI DC 150 | Φ 900 | 3 | 150 |

| DMI DC 200 | Φ 1250 | 3 | 200 |

| DMI DC 250 | Φ 1250 | 4 | 250 |

Product Images

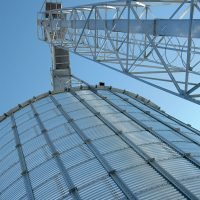

Catwalks

Catwalks are used to carry the horizontal grain handling equipments. By the help of catwalks; maintenance, repair and control work of these handling equipments can be done easily.

Product Images

Chain Conveyors

Chain conveyors are used for horizontal handling of grain. Conveyor chain is heat threated and case hardened with press-fir joints. Uhmw plastic pedals are mounted on high tensile strength conveyor chain.by those plastic pedals, friction inside the conveyor is reduced so the required power is also reduced helping conveyor efficiency. Also, by those plastic pedals, steel to steel contact is eliminated.

Technical Specifications

| Capacity (tons/hour) | 25 | 50 | 100 | 150 | 200 | 250 | 300 |

Product Images

Compact Feed Mills

Dassilos® manufactures compact feed mills. Including the pelleting line, Dassilos® offers turnkey solutions.

Product Images

Hangars

Dassilos® manufactures hangars for flat storage. They are manufactured as isolated or without isolation at different types.

Product Images

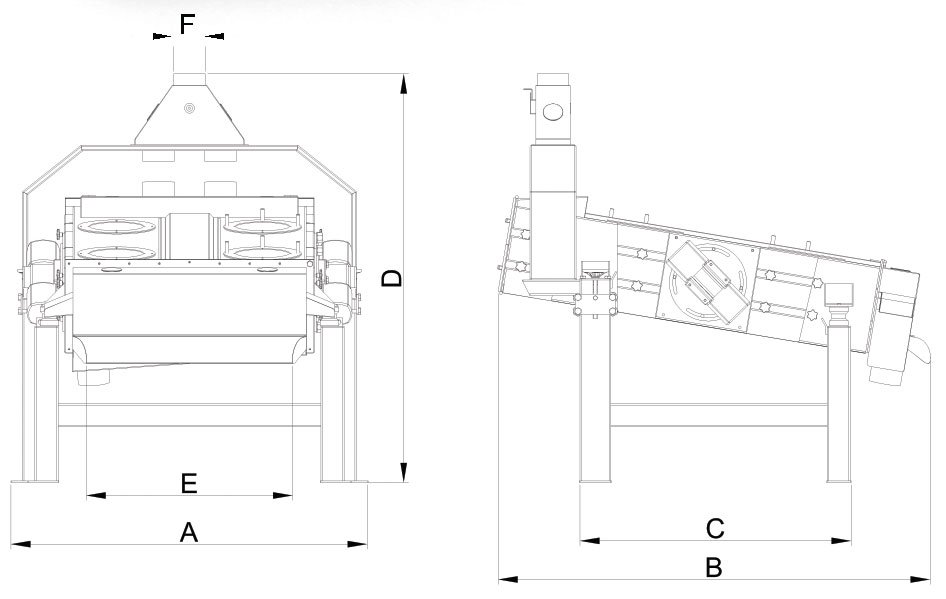

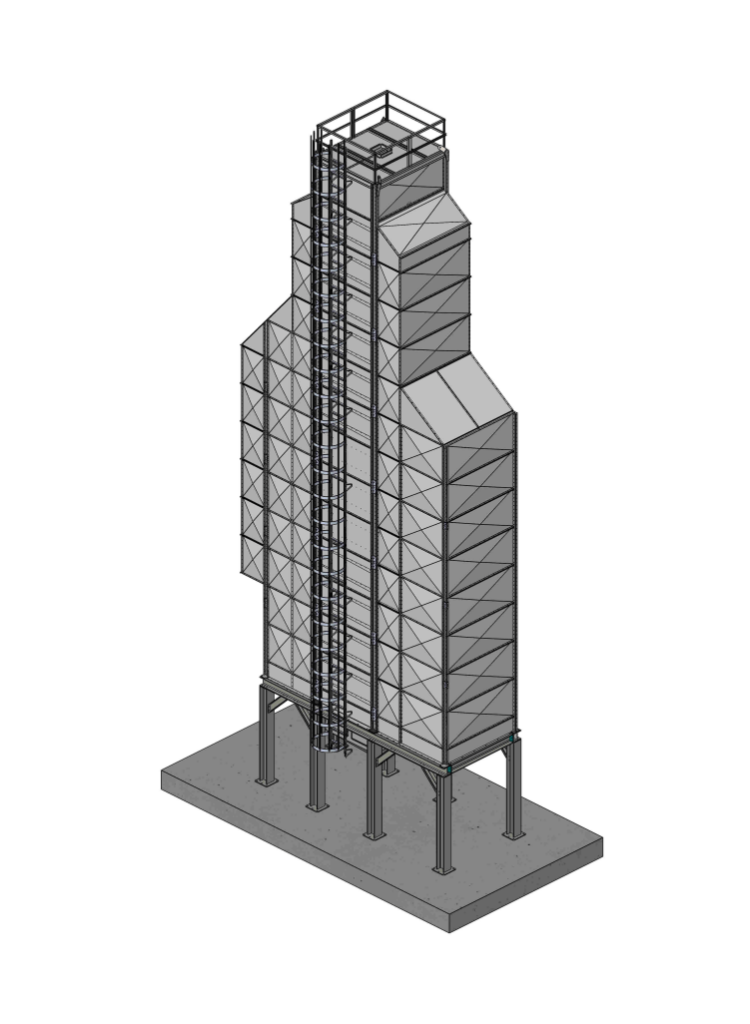

Grain Drying Systems

Manufactured for Energy Efficiency: Some of the air in the cooling section is mixed with hot air, thus circulating the air inside the dryer. Thus, fuel economy is provided. Especially in cold outdoor temperatures, the energy efficiency that occurs is high.

Suitable for all grains: Since the grains are away from the combustion chamber during drying, these types of dryers are recommended for all grains, especially oilseeds.

Drying can be done using a wide variety of fuels. With a separate boiler design for each fuel, coal, wood, rice husk, sunflower husk, natural gas, diesel, LPG, biogas, fuel oil, any biomass can be used as fuel in this dryer.

Manufactured to dry without damaging the grain: Thanks to the low grain temperature;

Grain properties are minimally affected.

Thanks to the superior design of the mixed flow dryer, the grain never reaches a high grain temperature inside the dryer.

High grain temperature reduces the protein content of grains used as feed raw materials and increases grain breakage. Surface cracks increase especially in rice and corn. It causes the inner part of the grain to shrink. It reduces flour yield in dry milling and starch ratio in wet milling. It reduces oil quality and yield in oil seeds. It reduces the baking quality of wheat.

High grain temperature also affects seed yield by reducing germination value.

Homogeneous and uniform drying: Thanks to its superior design,

Each grain in the dryer encounters the drying air equally.

Thanks to the numerous V channels in the drying tower, the grain is mixed repeatedly as it descends from the drying tower.

Drying is not done by first heating and then cooling, but by both heating and cooling at the same time. Thus, the grain grain temperature does not increase in a way that will cause yield loss.

Since there is no grain exposed to hot air more or less than others, homogeneous drying is achieved on a grain and product basis.

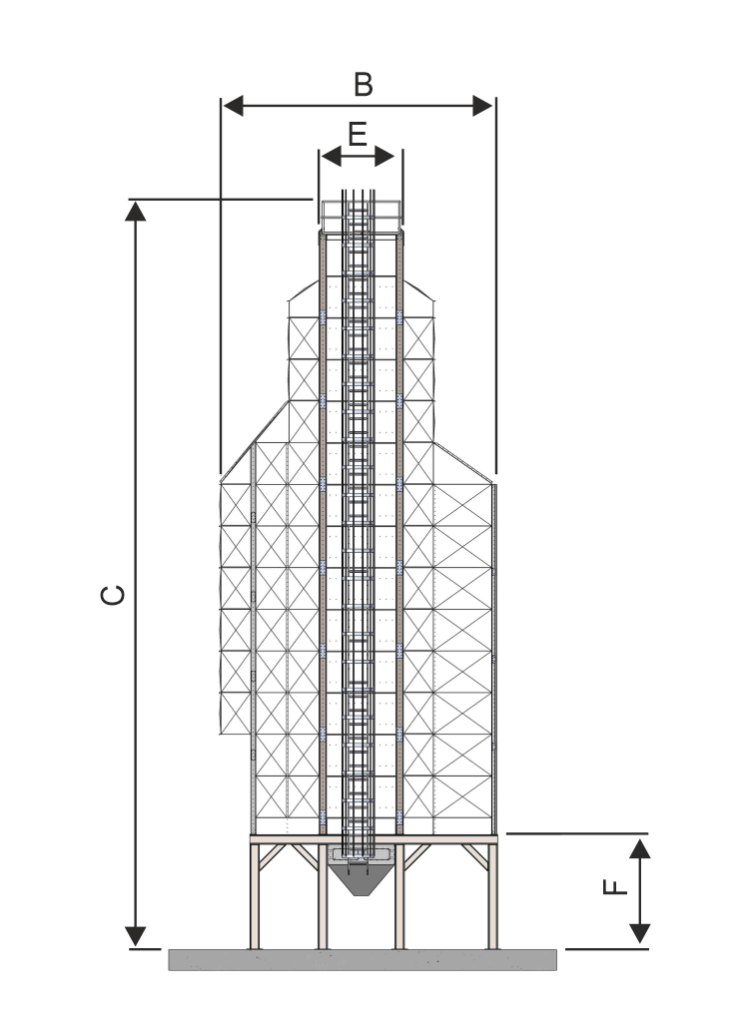

Technical Specifications

| CAPACITY TON / S | A (m) | B (m) | C (m) | D (m) | E (m) | F (m) |

|---|---|---|---|---|---|---|

| 15 | 2,35 | 6,6 | 14,8 | 3,4 | 2 | 2,75 |

| 20 | 2,35 | 6,6 | 16,8 | 3,4 | 2 | 2,75 |

| 25 | 2,35 | 6,6 | 19,5 | 3,4 | 2 | 2,75 |

| 35 | 4,5 | 6,6 | 19,5 | 5,6 | 2 | 2,75 |

| 50 | 4,5 | 7,25 | 19,5 | 5,6 | 2 | 2,75 |

| 75 | 6,7 | 7,25 | 19,5 | 7,7 | 2 | 3,55 |

| 100 | 6,7 | 7,25 | 26,5 | 7,7 | 2 | 3,55 |

Product Images